I recently built Atlantis Models' repop of Aurora's 1/48th scale 8

inch howitzer. I thought it would be a walk down memory lane, as I thought I

remembered that about 50 years ago I built Aurora's Long Tom, which is the same

kit except for the gun tube. Now I think the kit I built back then was probably

Hasegawa's 1/72 Long Tom. Either kit is very play-worthy and fun for kids (and for modelers who can still remember being kids). One of these toys - I mean models (wink!) - can be just the thing to get the modeling mojo going again!

I recently built Atlantis Models' repop of Aurora's 1/48th scale 8

inch howitzer. I thought it would be a walk down memory lane, as I thought I

remembered that about 50 years ago I built Aurora's Long Tom, which is the same

kit except for the gun tube. Now I think the kit I built back then was probably

Hasegawa's 1/72 Long Tom. Either kit is very play-worthy and fun for kids (and for modelers who can still remember being kids). One of these toys - I mean models (wink!) - can be just the thing to get the modeling mojo going again!

The instructions tell you how to assemble the kit in travel mode,

but let you know when not to use cement so the play features all work. The upper carriage elevates and traverses, the

gun tube recoils, the breech opens (though it doesn't represent the breech

block at all accurately). The lower carriage has separate chock plates and

trail plates which can be stowed for travel or mounted for firing (more on this

below, since there are problems, mainly with the clarity of the instructions).

The split trails swing and can be joined to the limber plate and mounted on the

limber, and the lower carriage can be dropped out of the tandem wheel assembly

that supports it in travel mode (more on this below, as well). And of course,

the wheels all turn.

The instructions tell you how to assemble the kit in travel mode,

but let you know when not to use cement so the play features all work. The upper carriage elevates and traverses, the

gun tube recoils, the breech opens (though it doesn't represent the breech

block at all accurately). The lower carriage has separate chock plates and

trail plates which can be stowed for travel or mounted for firing (more on this

below, since there are problems, mainly with the clarity of the instructions).

The split trails swing and can be joined to the limber plate and mounted on the

limber, and the lower carriage can be dropped out of the tandem wheel assembly

that supports it in travel mode (more on this below, as well). And of course,

the wheels all turn.

The kit

originally came out in 1958, and although it purported to be a WWII howitzer,

it's got features that were only seen later. Notably, the tires have gnarly off-road

tread, and I think the mount on the limber where the trails are attached is a

later version as well. So I decided that my howitzer lives in 1958. I painted

the figures so their uniforms are Olive Green, not Olive Drab – mostly. Old

stocks of Olive Drab were used up after the war, and from what I've read may

still have been in use in 1958. Boots were now polished black, and enlisted rank insignia were

no longer buff over blue. They look like olive green over blue, but I don't

know if Olive Green was the specified color. President Truman had integrated

the armed forces a decade before, so I painted the soldier holding the wrench to

be a black man. I chose to paint his uniform Olive Drab, to represent the old

stock being used up, though it's hard to see the difference.

The kit

originally came out in 1958, and although it purported to be a WWII howitzer,

it's got features that were only seen later. Notably, the tires have gnarly off-road

tread, and I think the mount on the limber where the trails are attached is a

later version as well. So I decided that my howitzer lives in 1958. I painted

the figures so their uniforms are Olive Green, not Olive Drab – mostly. Old

stocks of Olive Drab were used up after the war, and from what I've read may

still have been in use in 1958. Boots were now polished black, and enlisted rank insignia were

no longer buff over blue. They look like olive green over blue, but I don't

know if Olive Green was the specified color. President Truman had integrated

the armed forces a decade before, so I painted the soldier holding the wrench to

be a black man. I chose to paint his uniform Olive Drab, to represent the old

stock being used up, though it's hard to see the difference.

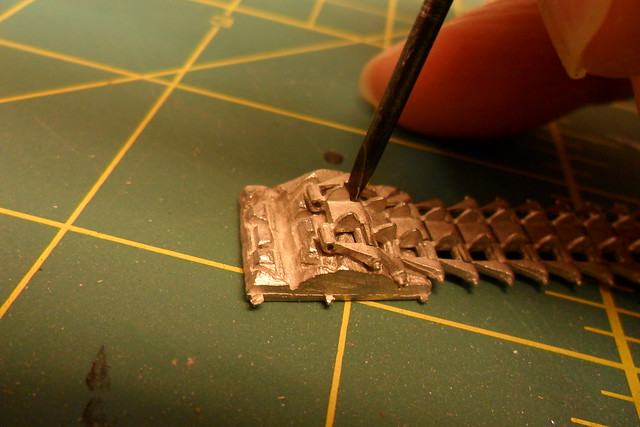

The kit has some assembly problems, and

I'll refer to the parts by name since that's how they're listed in the

instructions. In Step 25, the springs are cemented to the forward and rear

tandem axles, but the mating surfaces are shaped differently: flat on the

springs but round on the axles. This means there is very little contact area.

This problem is exacerbated in Step 36, when the ends of the cross beam axle

are to be snapped into the holes in the springs on the tandem wheel assembly. The

snap fit requires a fairly tight tolerance for

the distance between the springs – too far apart, and the carriage just falls

out; too close together and it pries the springs apart, breaking them off the

axles. If I build another, I'll be sure to engineer the spring/tandem axle

assembly at the outset to get the springs firmly attached with the correct spacing.

The four small airbrake diaphragms (Steps 26 and 29) are also easily knocked

off when attaching the cross beam axle, and I'm not sure if there is any way

they can go on straight and not get in the way of the cross beam axle.

The kit has some assembly problems, and

I'll refer to the parts by name since that's how they're listed in the

instructions. In Step 25, the springs are cemented to the forward and rear

tandem axles, but the mating surfaces are shaped differently: flat on the

springs but round on the axles. This means there is very little contact area.

This problem is exacerbated in Step 36, when the ends of the cross beam axle

are to be snapped into the holes in the springs on the tandem wheel assembly. The

snap fit requires a fairly tight tolerance for

the distance between the springs – too far apart, and the carriage just falls

out; too close together and it pries the springs apart, breaking them off the

axles. If I build another, I'll be sure to engineer the spring/tandem axle

assembly at the outset to get the springs firmly attached with the correct spacing.

The four small airbrake diaphragms (Steps 26 and 29) are also easily knocked

off when attaching the cross beam axle, and I'm not sure if there is any way

they can go on straight and not get in the way of the cross beam axle.

Minor assembly problems occur with the trail ground support plates

and chock plates. The instructions don't give very clear indications on where

the former go when stowed (Step 40), and the inset photo of the completed

models shows them glued to the underside of the trails. Correctly assembled,

they slide into the trail plate hangers on the inside faces of the trails. Care

must be taken to attach the trail plate hangers properly in Step 33 so the

support plates will slide in and out. The notches in the lower gun carriage and

bottom plate to allow for the deployed chock plates need filing out, as you'll

find out when test fitting them. The instructions don't tell how to attach

these or the trail support plates when deployed for firing mode, but you can

see the notches on the underside of the carriage and the ends of the trails.

Both types of plates form a right angle with welded gussets on the inside of

the angle, and are deployed with the gussets facing forward so the recoil

doesn't pry the welds apart.

Minor assembly problems occur with the trail ground support plates

and chock plates. The instructions don't give very clear indications on where

the former go when stowed (Step 40), and the inset photo of the completed

models shows them glued to the underside of the trails. Correctly assembled,

they slide into the trail plate hangers on the inside faces of the trails. Care

must be taken to attach the trail plate hangers properly in Step 33 so the

support plates will slide in and out. The notches in the lower gun carriage and

bottom plate to allow for the deployed chock plates need filing out, as you'll

find out when test fitting them. The instructions don't tell how to attach

these or the trail support plates when deployed for firing mode, but you can

see the notches on the underside of the carriage and the ends of the trails.

Both types of plates form a right angle with welded gussets on the inside of

the angle, and are deployed with the gussets facing forward so the recoil

doesn't pry the welds apart.

The sector gear (Step 9) is supposed to hold the upper carriage at

various angles of elevation, snapping over the stepped shaft (Step 13) as the

elevation angle is adjusted. This movement is very sensitive to any alignment error

in Step 9, so I found I had to file the sector gear teeth until it went between

minimum and maximum elevation with a light click. Step 42 is also a little confusing

if you trust the photo in the instructions. The hitch lock should be oriented

as shown in the diagram.

The sector gear (Step 9) is supposed to hold the upper carriage at

various angles of elevation, snapping over the stepped shaft (Step 13) as the

elevation angle is adjusted. This movement is very sensitive to any alignment error

in Step 9, so I found I had to file the sector gear teeth until it went between

minimum and maximum elevation with a light click. Step 42 is also a little confusing

if you trust the photo in the instructions. The hitch lock should be oriented

as shown in the diagram.

Some filler is needed for the inevitable ejector pin marks and to

eliminate the seam in the assembled gun tube. Yes, kits of this vintage lack

slide molded barrels! Back in the good old days before slide molding, instead

of wailing and gnashing our teeth, we'd roll up our sleeves and we'd putty,

sand, and primer the gun tube for as many go-arounds as it took to get a smooth

barrel with a precisely centered round bore. So that's what I did, and frankly

it wasn't that much trouble. The vinyl tires were the worst molded parts. All

the way around the tire was a weird hump across the tread, affecting some tires

more than others. It took a lot of sanding until none of the ten tires looked

noticeably like factory rejects.

Some filler is needed for the inevitable ejector pin marks and to

eliminate the seam in the assembled gun tube. Yes, kits of this vintage lack

slide molded barrels! Back in the good old days before slide molding, instead

of wailing and gnashing our teeth, we'd roll up our sleeves and we'd putty,

sand, and primer the gun tube for as many go-arounds as it took to get a smooth

barrel with a precisely centered round bore. So that's what I did, and frankly

it wasn't that much trouble. The vinyl tires were the worst molded parts. All

the way around the tire was a weird hump across the tread, affecting some tires

more than others. It took a lot of sanding until none of the ten tires looked

noticeably like factory rejects.

Paint is mainly rattlecan Krylon camo olive with light weathering

except where the rubber literally meets the road, or the lack of a road (and

takes some with it). The decals are a new addition by Atlantis and appropriate

for postwar howitzers, and though I doubt they represent any actual markings,

pictures can be found of howitzers bearing stars, the words "U. S.

ARMY," and nicknames, all of which are on the decal sheet. It wasn't easy

to find room for them all, but I managed. They went down nicely over a coat of

Future and coated with MicroSol. I had no trouble keeping them from silvering

(some decals just seem to suck air in under them, so they'll silver no matter

what you do). They are not the thinnest decals and glossy to boot, but brushing

on some flat coat knocked down the gloss and all but completely hid the edge of

the carrier film.

Paint is mainly rattlecan Krylon camo olive with light weathering

except where the rubber literally meets the road, or the lack of a road (and

takes some with it). The decals are a new addition by Atlantis and appropriate

for postwar howitzers, and though I doubt they represent any actual markings,

pictures can be found of howitzers bearing stars, the words "U. S.

ARMY," and nicknames, all of which are on the decal sheet. It wasn't easy

to find room for them all, but I managed. They went down nicely over a coat of

Future and coated with MicroSol. I had no trouble keeping them from silvering

(some decals just seem to suck air in under them, so they'll silver no matter

what you do). They are not the thinnest decals and glossy to boot, but brushing

on some flat coat knocked down the gloss and all but completely hid the edge of

the carrier film.

One particular mistake I made (and I always make mistakes!) was with the piston rods in the elevating cylinders. I painted them with Model Master Chrome Silver enamel and found they were a tight fit, so I added a drop of 3-in-1 oil to each so the elevation mechanism would work. As a result, the oil softened the paint so that it will probably never be completely dry, and I kept getting silver fingerprints on the howitzer during assembly. The piston rods don't look so great now, either.

I wanted to display the completed model on a simple diorama base to keep all the partsand figures together. I glued two seven by nine inch pieces of corrugated cardboard together with their corrugations at right angles to each other, clamped under the weight of a small anvil. The resulting base is very stiff. I applied MDF sawdust, brown spray paint, and Woodland Scenics foliage. To support the figures, I heated a straight pin and shoved it into one foot of each figure. After painting the figures, I cut the pins so only about 1/8" stuck out, then I stuck the figures to the diorama base like thumbtacks.